MOTTLED PRINT

Mottled print is a common problem , when trying to print good quality consistent solids in flexo. The surface of the print appears like orange peel, with inconsistent colour and non-uniform appearance

Cause

Printing form with uneven or un-clean surface

Ink viscosity or concentration, too low

Residual chemicals from the plate-making process, still on surface

Dirty or scratched impression cylinder

In-correct ink transfer on the printing form or substrate

Ink not wetting on printing form or substrate

Solution

1 Increase the printing pressure between the printing form and substrate

2 Increase the ink viscosity or ink film thickness.

3 Modify ink to correct viscosity or opacity. Check the balance of solvent in the ink. If necessary change the ink

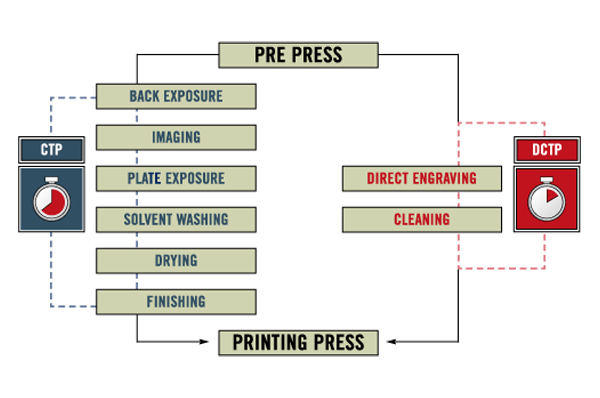

4 Wash the printing form to remove residual chemicals. If necesary remake the printing form

5 Properly clean the impression cylinder

6 Use softer or more compatible plate or cushion tape

7 Check surface treatment of the substrate

Helmut Mathes, troubleshooting defects supplied curtesey of Flexo & Gravure Int''l 2011

INK TRANSFER - ANILOX

The shape and consistency of anilox cells makes a huge impact on ink transfer and cleanliness of the inking process to the printing plate.

Read moreDIRTY ANILOX

Dried ink in anilox cells, can cause significant change in print densities. The FlexoStar laser can clean dried ink from even the smallest cells.

Read more